RCD testing (or safety switch testing) isn’t just a compliance checkbox—it’s a lifesaver. Under Australian Standards AS/NZS 3760:2022, workplaces must test these devices regularly to prevent electrocutions, fires, and six-figure WHS fines.

Here’s how often your Perth business needs checks, based on your industry risk level:

What is RCD Testing?

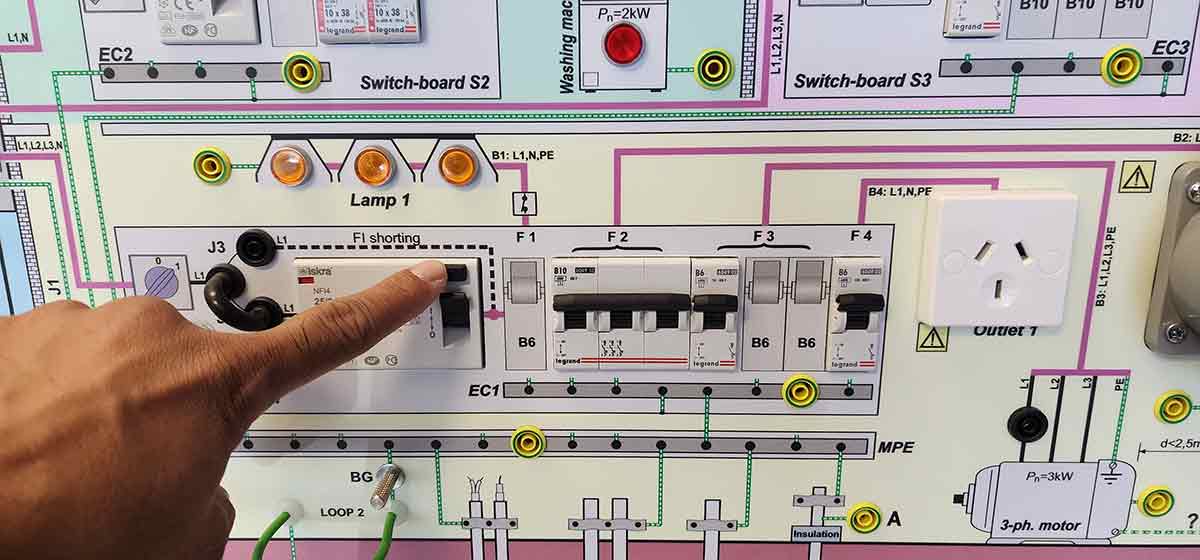

RCDs (Residual Current Devices) work continuously monitor electrical flow in active (supply) and neutral (return) conductors of an electric circuits.

They quickly shut off power if they detect an imbalance, such as a fault in the circuit or electricity leaking through a person.

Why Regular RCD Testing Is Necessary?

RCDs cut power within 40 milliseconds during faults—but only if working correctly. Over time, RCDs can wear out, making regular testing essential to ensure they function properly.

Testing ensures Residual Current Devices function correctly by simulating electrical faults. Regular checks confirm they trip fast enough to protect workers from shocks or fires. Regular testing helps catch potential failures before they turn into safety risks.

- Prevent Device Degradation: Dust, moisture, and wear can delay RCD response times.

- Stop Fires/Shocks: Prevent electrocutions by faulty RCDs.

- Avoid Penalties: Non-compliance penalties under WHS Act 2020.

RCD Testing Requirements in Australia: How Often Should You Test?

Sticking to a routine RCD testing schedule helps ensure workplace safety, prevents electrical hazards, and meets legal compliance.

| RCD Testing Interval | WorkPlace Type | Example |

|---|---|---|

| Every 3 months | Low-Risk Sites | Offices, Retails |

| Every 6–12 months | High-Risk Sites | Constructions, Industrial |

Immediate post-incident inspection is required after:

- Floods/water damage

- Electrical modifications/New electrical work

- Electric equipment damage

At Neon Safety, we offer certified RCD testing services to keep your business safe and compliant.